Control valve air blowing device

A technology of blowing device and control valve, which is applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., which can solve the problem of difficult blowing on the end face and outer circle of workpieces, and blowing on the inner holes of workpieces. Difficult, uneven blowing, etc., to achieve good blowing effect, high blowing efficiency, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

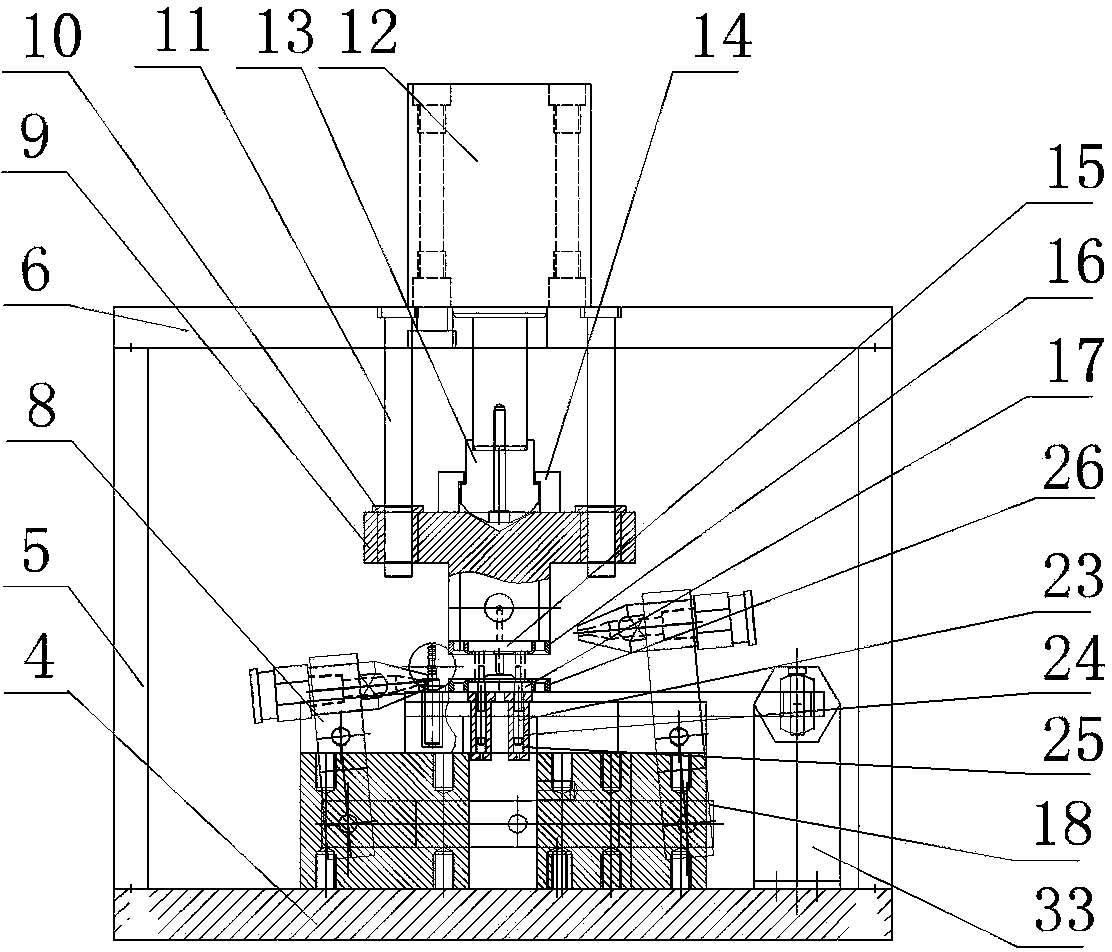

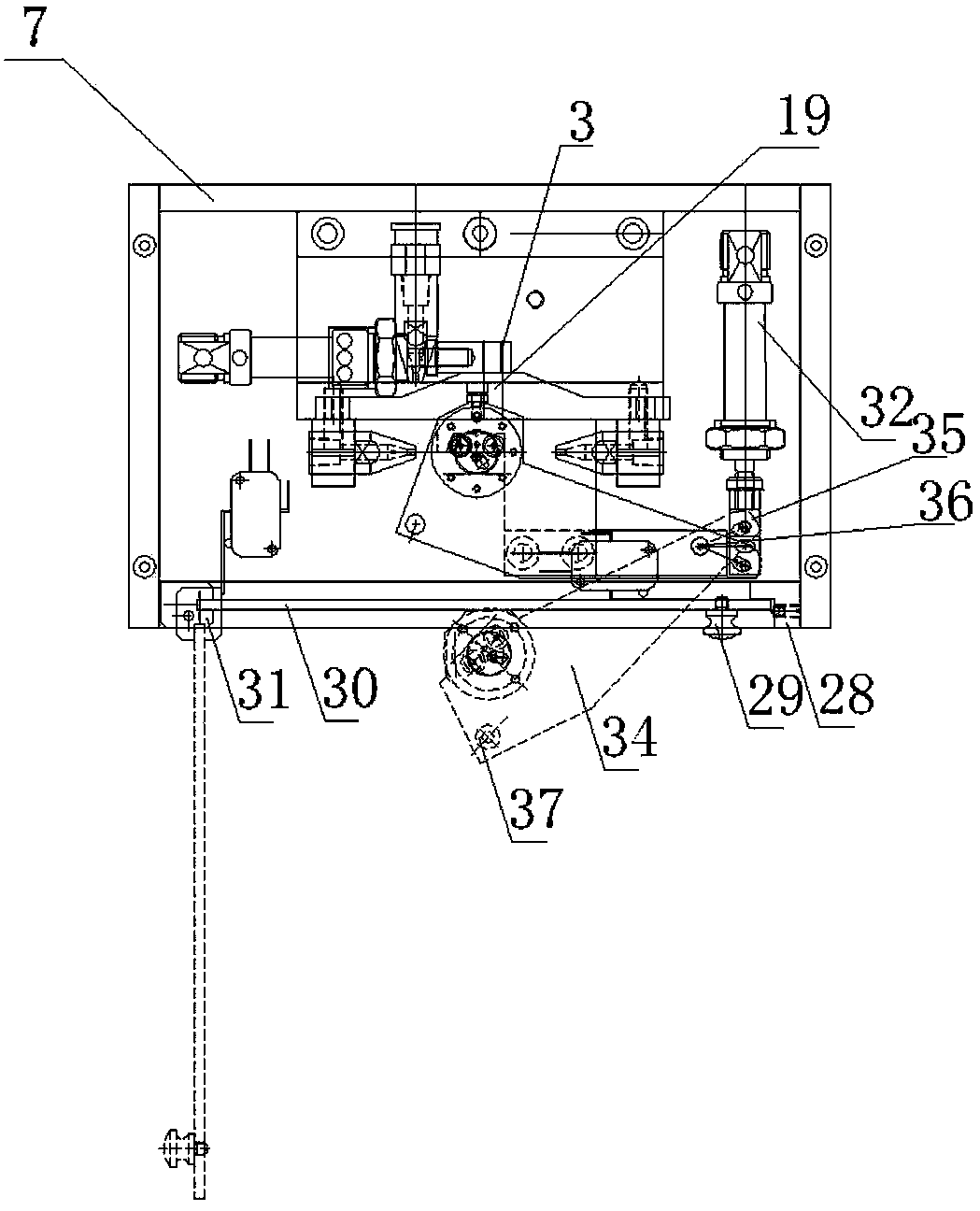

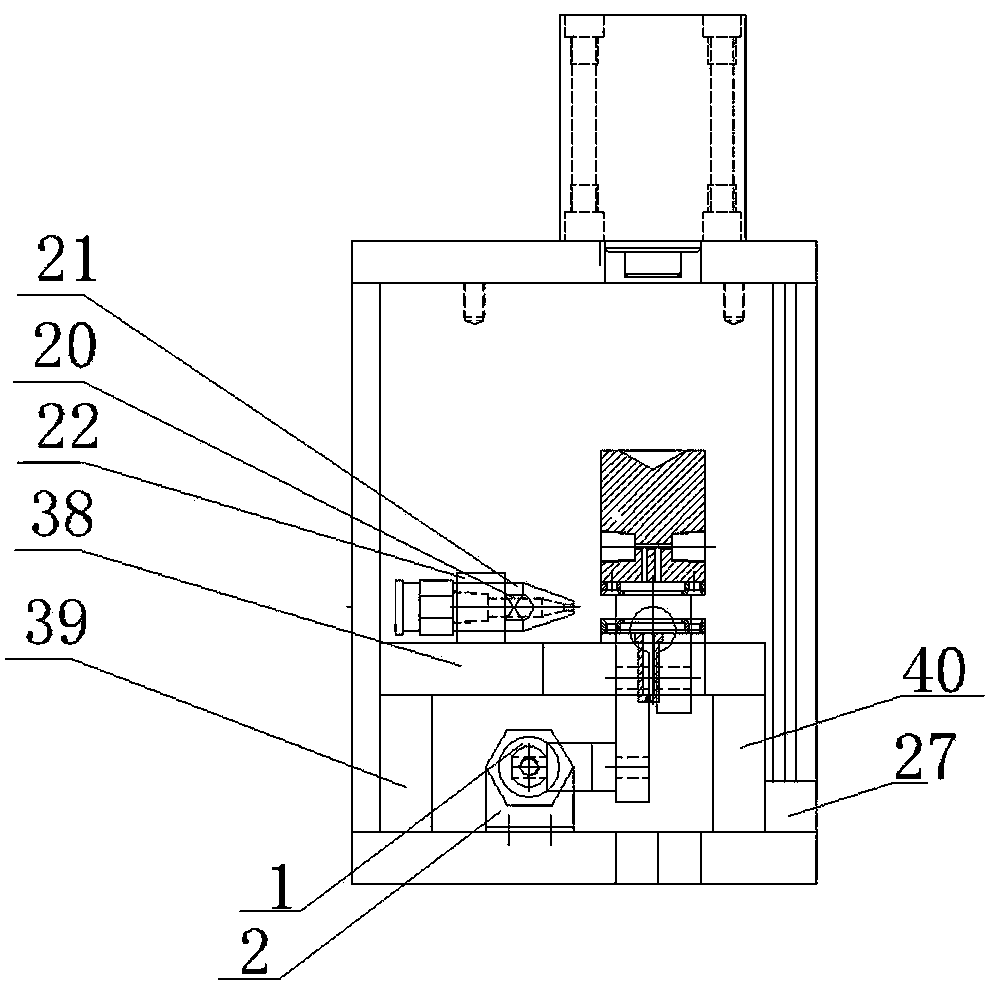

[0030] Such as Figure 1-3 As shown, a blowing device for a control valve includes a casing, a supporting part arranged in the casing, a clamping part, a blowing part and a pressing part,

[0031] The clamping part includes an indexing plate 34, on which a valve body positioning pin 23 and a valve body positioning sleeve 24 for clamping the valve body are arranged, and a spring 25 is installed below the valve body positioning pin 23. , the spring 25 is installed in the valve body positioning sleeve 24, and the positioning plate 34 is also provided with a valve core positioning sleeve 37 for clamping the valve core;

[0032] Described pressing part comprises press seat 9 and cylinder 12, and described cylinder 12 below is equipped with spherical head 13, and described press seat 9 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap